Products & Services

MACHINE FOR STONE INDUSTRY–Granite, Marble, Quartz, Ceramics

As the exclusive partner for Simec and SITI B&T in India, we offer the latest generation of stone and ceramic processing technologies, including:

Block Cutting Machines

Block cutting machines for stone, granite, and marble are designed to cut large natural stone blocks into slabs or tiles with high precision. They use diamond-tipped circular blades or wire saws, often with water cooling to reduce heat and dust. Heavy-duty frames and CNC controls ensure smooth, accurate, and automated cutting processes. These machines are essential in quarries and fabrication plants for producing finished stone products used in construction and design.

Polishing Lines

Polishing lines for stone are industrial systems used to polish slabs of granite, marble, and other natural stones to achieve a smooth, glossy, or matte finish. These lines typically consist of a series of rotating abrasive heads that progressively grind and polish the stone surface as it moves along a conveyor. Water is used throughout the process to cool the tools and reduce dust, ensuring a high-quality surface finish. Polishing lines are essential in stone fabrication facilities, allowing for high-speed, consistent finishing of slabs before they are cut or installed.

Multiwire Saw

A multiwire saw is an advanced stone cutting machine used to slice large blocks of granite, marble, and other natural stones into multiple slabs simultaneously. It operates using dozens of diamond-coated wires that run in parallel, allowing for fast, precise, and uniform cuts with minimal material waste. The system is water-cooled to reduce heat and dust during cutting, improving both wire lifespan and slab quality. Multiwire saws are widely used in modern stone processing plants for their efficiency, high production output, and ability to handle even the hardest stones with reduced energy consumption.

Quartz Manufacturing Plants

Quartz manufacturing plants are industrial facilities where engineered quartz surfaces—commonly used for countertops, tiles, and wall cladding—are produced using a combination of natural quartz crystals, resins, pigments, and additives. The process typically involves mixing the raw materials, molding and compacting them under high pressure and vacuum, and then curing the slabs in ovens to harden the surface. After curing, the slabs go through calibration, polishing, and quality control to achieve the desired thickness, finish, and appearance. These plants use advanced machinery and automation to ensure consistency, durability, and a wide range of colors and patterns, making engineered quartz a popular choice in residential and commercial interiors.

Ceramic Tile Production Lines

Ceramic tile production lines are automated systems used to manufacture ceramic tiles from raw materials like clay, feldspar, sand, and kaolin. The process typically involves mixing and grinding raw materials, spray drying to form powder, then pressing the powder into tile shapes using hydraulic presses. The tiles are then dried, glazed (if needed), and fired in high-temperature kilns to achieve strength and finish. Modern production lines include advanced technologies for digital printing, automated handling, and quality control, enabling high-speed, consistent production of tiles in various sizes, textures, and designs.

CNC Machining Centers

CNC machining centres are advanced manufacturing machines that use computer numerical control (CNC) to automate and precisely perform cutting, drilling, milling, and shaping operations on materials like metal, stone, wood, or composites. These machines operate along multiple axes (typically 3 to 5 or more), allowing for complex and highly accurate part production. In stone processing, CNC centres are used for creating countertops, sinks, engravings, and decorative elements with high precision and repeatability. Equipped with tool changers, touch-screen interfaces, and CAD/CAM integration, CNC machining centres are essential in modern fabrication for boosting productivity, reducing manual labor, and ensuring consistent quality.

Turnkey Engineering Projects

Turnkey Engineering

From design to deployment, we manage complete turnkey engineering projects tailored to client needs. Our solutions integrate cutting-edge technology with practical engineering expertise, ensuring timely delivery, seamless execution, and long-term operational value.

Automation & Digital Transformation

Automation & Digital Transformation

We specialize in industrial automation, retrofits, and smart fabrication systems that drive operational efficiency and productivity. By combining modern automation technologies with industry best practices, we help clients embrace digital transformation and achieve sustainable growth.

Fabrications – Industrial All Types

We specialize in heavy-duty and custom fabrication solutions for multiple sectors

Industrial sheds & steel structures

Industrial sheds and steel structures are large, durable buildings made primarily from prefabricated steel components, designed to support manufacturing, warehousing, processing, and other industrial operations. These structures offer quick installation, high strength-to-weight ratio, and long-term durability with minimal maintenance. They can be customized in size, shape, and layout to suit specific industry needs, including overhead cranes, mezzanines, or large open-span areas. Steel sheds are widely used due to their cost-effectiveness, flexibility, and ability to withstand harsh environmental conditions.

Stainless steel & mild steel storage tanks

Stainless steel and mild steel storage tanks are industrial containers used to store liquids, chemicals, water, and other materials in sectors like manufacturing, food processing, pharmaceuticals, and wastewater treatment. Stainless steel tanks offer excellent resistance to corrosion, making them ideal for storing hygienic or corrosive substances, such as food-grade products or acids. Mild steel tanks, while more cost-effective, are typically used for storing non-corrosive materials and often require protective coatings to prevent rust. These tanks can be custom-built in various sizes, shapes, and configurations (vertical, horizontal, pressurized, or atmospheric) depending on the application. Both types are valued for their durability, strength, and ability to be integrated into automated systems.

Conveyor systems & material handling units

Conveyor systems and material handling units are essential industrial solutions designed to efficiently move, transport, or manage materials within a facility. Conveyor systems use belts, rollers, chains, or modular components to transfer goods between different stages of production, packaging, or storage with minimal manual effort. Material handling units include equipment like cranes, lifts, hoists, trolleys, and automated guided vehicles (AGVs) to assist in lifting, positioning, or relocating heavy or bulky loads. These systems improve productivity, safety, and workflow in industries such as manufacturing, warehousing, mining, and logistics. Modern systems can be automated and integrated with sensors or software for enhanced control, tracking, and efficiency.

Custom jigs, fixtures & production support equipment

Custom jigs, fixtures, and production support equipment are specially designed tools used to enhance accuracy, efficiency, and consistency in manufacturing and assembly processes. Jigs guide the cutting or drilling tools, while fixtures securely hold workpieces in place during machining, welding, or inspection. These components are tailored to specific parts or operations, helping reduce setup time, minimize errors, and improve repeatability. Production support equipment includes items like tool holders, assembly aids, gauges, and ergonomic workstations that streamline operations and improve safety. Custom-built solutions are critical in high-precision or high-volume industries such as automotive, aerospace, electronics, and metal fabrication.

Retrofits – All Industries

We extend the life of your existing machinery through

Mechanical upgrades & performance enhancements

Mechanical upgrades and performance enhancements involve modifying or replacing existing components in machinery or systems to improve efficiency, reliability, output, or lifespan. This can include upgrades like higher-efficiency motors, advanced control systems, precision components, improved lubrication systems, or retrofitting with automation features. Such enhancements help reduce downtime, lower maintenance costs, and increase overall productivity. They are especially valuable for aging equipment, allowing businesses to extend the useful life of assets without full replacement. Performance upgrades are commonly applied in industries such as manufacturing, processing, energy, and material handling, where consistent operation is critical.

Energy efficiency improvements

Energy efficiency improvements refer to upgrades or modifications made to systems, equipment, or processes to reduce energy consumption while maintaining or enhancing performance. This can include installing energy-efficient motors, LED lighting, variable frequency drives (VFDs), insulation, heat recovery systems, and optimizing process controls. In industrial settings, improving energy efficiency leads to lower operational costs, reduced carbon emissions, and compliance with environmental standards. These improvements often involve energy audits to identify inefficiencies and recommend targeted actions. Energy-efficient operations also contribute to increased equipment lifespan and overall system reliability, making them a smart investment for long-term sustainability.

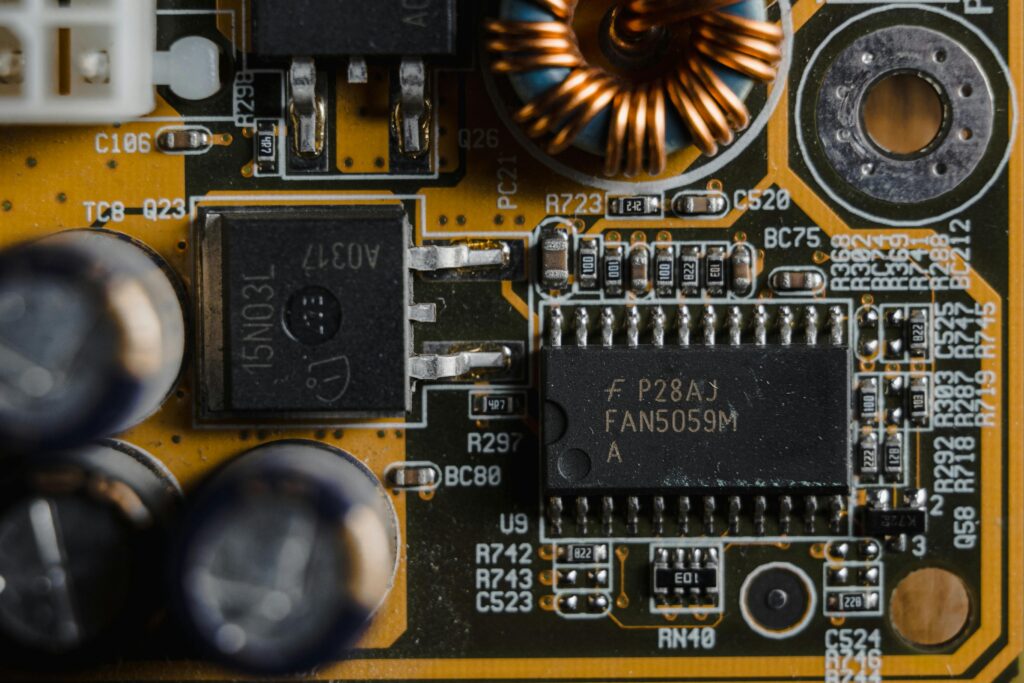

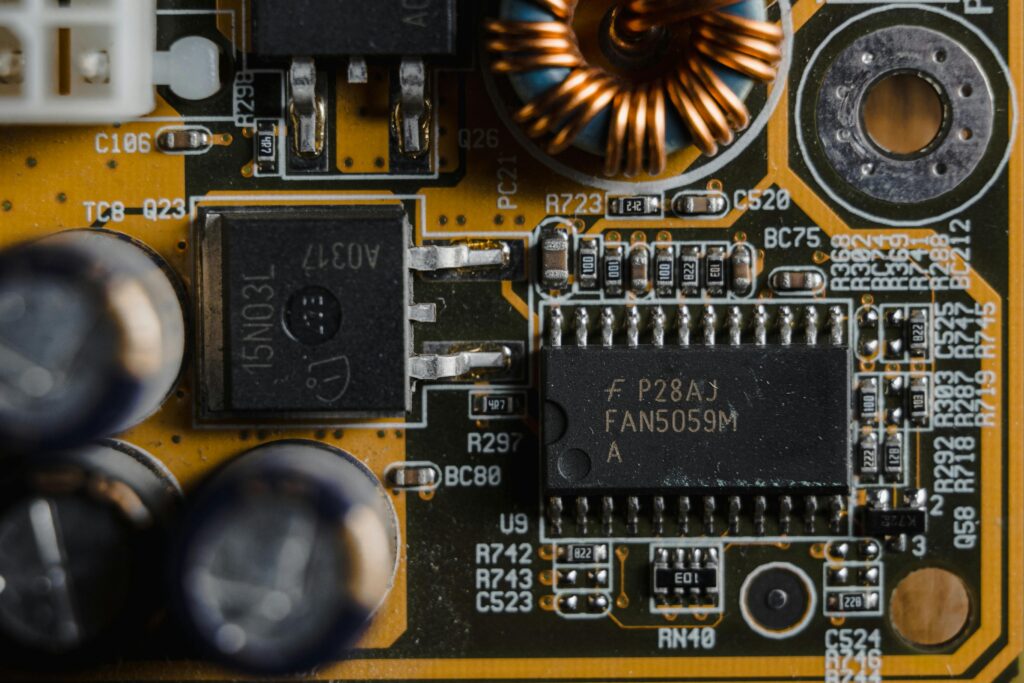

Integration of modern control systems

Integration of modern control systems involves upgrading existing machinery or processes with advanced technologies like PLC (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interfaces), and IoT-based sensors. These systems enable real-time monitoring, automation, data logging, and remote control, leading to improved operational efficiency, precision, and decision-making. Modern control systems can be customized to suit specific industrial workflows and are often integrated with existing equipment to enhance performance without full replacement. This integration supports predictive maintenance, energy optimization, and seamless communication across different production units. It is a key step toward smart manufacturing and Industry 4.0 readiness.

Machine Repairs & Upgradations

Full-scope repair, maintenance, and upgrade services

Emergency breakdown repairs

Emergency breakdown repairs involve rapid response services to restore malfunctioning or failed machinery and equipment in critical industrial operations. These repairs are aimed at minimizing downtime, production loss, and safety risks caused by unexpected failures. Skilled technicians diagnose the issue on-site, carry out immediate repairs or temporary fixes, and, if needed, arrange for part replacements or system overhauls. Emergency repair services often cover mechanical, electrical, hydraulic, or control system failures. Quick and reliable breakdown response is essential for industries like manufacturing, processing, logistics, and utilities, where equipment uptime is vital for continuous operation.

Preventive maintenance programs

Preventive maintenance programs are structured plans designed to regularly inspect, service, and maintain equipment to prevent unexpected failures and extend machinery lifespan. These programs include scheduled tasks such as lubrication, cleaning, part replacement, calibration, and system checks, based on manufacturer recommendations or operational data. By addressing wear and potential issues early, preventive maintenance reduces downtime, repair costs, and safety risks, while improving equipment efficiency and reliability. Programs can be tailored to specific machines or entire facilities and often include maintenance logs, checklists, and performance tracking. Implementing a preventive maintenance strategy is a key component of lean operations and asset management in industrial environments.

Component replacement & system optimization

Component replacement and system optimization involve updating worn-out, outdated, or underperforming parts with new or improved components to restore or enhance overall system performance. This process may include replacing motors, bearings, control units, sensors, or other critical parts to improve efficiency, safety, and reliability. Alongside replacements, system optimization focuses on fine-tuning operations, adjusting settings, and integrating better technologies to achieve higher output, lower energy use, and reduced maintenance needs. These upgrades are especially valuable in aging equipment or systems facing frequent breakdowns or performance issues. Regular component replacement and optimization ensure that industrial operations remain cost-effective, competitive, and sustainable.

After-Sales Service

After-Sales Service & Support

Our commitment doesn’t end with project delivery. We provide comprehensive after-sales service, maintenance, and technical support to ensure maximum uptime and performance of your equipment. With a customer-first approach, we guarantee reliability and long-term satisfaction.

Machine for Stone Industry – Granite, Marble, Quartz, Ceramics

We provide advanced machinery solutions for natural and engineered stone processing, industrial fabrication, and manufacturing sectors. Our expertise lies in delivering high-performance machines that ensure precision, durability, and efficiency—helping businesses stay ahead in today’s competitive market.

Turnkey Engineering Projects

From design to deployment, we manage complete turnkey engineering projects tailored to client needs. Our solutions integrate cutting-edge technology with practical engineering expertise, ensuring timely delivery, seamless execution, and long-term operational value.

Automation & Digital Transformation

We specialize in industrial automation, retrofits, and smart fabrication systems that drive operational efficiency and productivity. By combining modern automation technologies with industry best practices, we help clients embrace digital transformation and achieve sustainable growth.

After-Sales Service & Support

Our commitment doesn’t end with project delivery. We provide comprehensive after-sales service, maintenance, and technical support to ensure maximum uptime and performance of your equipment. With a customer-first approach, we guarantee reliability and long-term satisfaction.

Global Technology Partnerships

Through collaborations with globally recognized principals, we bring world-class technologies to India and beyond. These partnerships enable us to offer innovative, reliable, and cost-effective solutions that meet the highest international standards.

Our Project

At Hopascopo Technologies, every project reflects our commitment to innovation, precision, and reliability. From engineering solutions to turnkey installations, we deliver projects that drive lasting impact across industries.

Our Work Culture

At Hopascopo Technologies, our work culture is built on collaboration, innovation, and trust. We empower our teams to grow, share ideas, and deliver excellence while fostering a supportive and inclusive environment.